Axenic System is one of the leading company engaged in architectural

designing, planning, installation, commissioning of HVAC and Turnkey

construction for cleanroom projects

Automotive

Table of Contents

AUTOMOTIVE CLEANROOMS STANDARDS

AXENIC SYSTEMS (established in 1995) functionally designs, builds and installs top-of-the-line cleanrooms to meet the requirements of the automotive industry. Our automotive cleanrooms can meet any classification requirements and are preferably suited for applications in automotive innovation, component manufacturing, and quality testing.

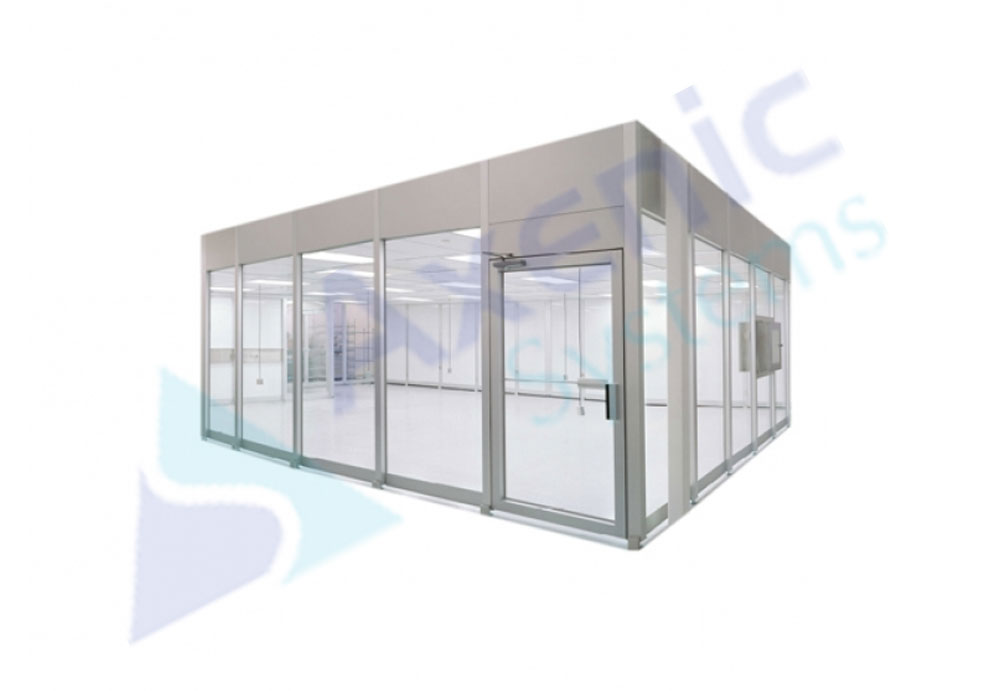

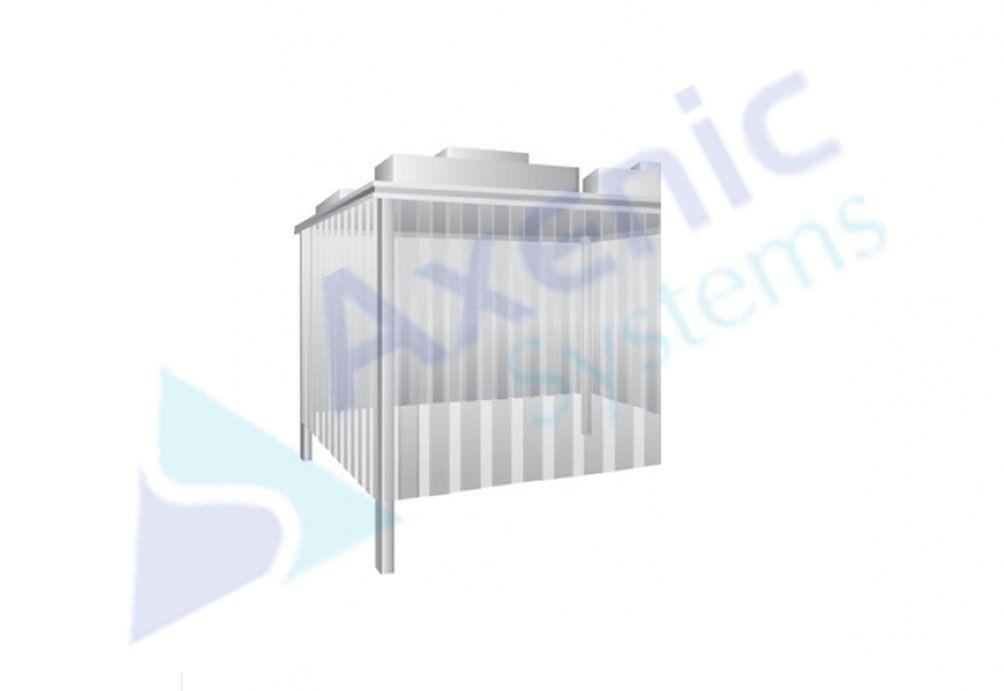

Modular cleanrooms are trustworthy, energy efficient, and easy to reconfigure, enlarge and upgrade, ideal for operations that require room to grow. As your projects evolve, AXENIC SYSTEMS will be there every step of the way, with cleanrooms designed to be arranged for whatever comes next.

Automotive cleanrooms are made to meet the cleanroom classifications and are fully equipped according to user application. Hardwall and Rigidwall modular cleanrooms can make use of the existing walls or be free-standing with standardized modular panels that are completely customizable for industry-specific equipment or standards.

WHAT IS AN AUTOMOTIVE CLEANROOM?

Automotive cleanrooms are used for the production, design, assembly, and testing of automotive parts and components. Since several of these products will be operated by ordinary people, they protect not only the future owners of the vehicle, but also other drivers on the road. The risks for functionality and security are high, and so are the regulations for assembling, manufacturing, and testing automotive parts and products.

The automotive industry needs cleanrooms for many applications at different levels of the supply chain. As vehicles are more innovative, manufacturing is less about just fitting the pieces together and is instead frequently becoming more difficult. Components are often interconnected through calibrated sensors, an intelligent computer system, and unique safety features. During the manufacturing procedure, sensitive elements can be compromised by changes in humidity, temperature, and pressure, and are particularly vulnerable to contamination and defects due to static electricity. A controlled environment is essential to ensure that all vehicles and components are assembled properly to prevent the threat of product malfunction or failure, and to guarantee customer well-being.

AUTOMOTIVE CLEANROOM STRUCTURE

Axenic cleanrooms can be free-standing or make use of existing walls and structures in your facility. They are made to be durable, top-quality, and high-performing. Our modular cleanrooms for the automotive industry are available as Hardwall or Rigidwall cleanrooms.

Search For Tags:- list of clean room manufacturers, clean room manufacturers, modular clean room manufacturers